How To Cut Flexible Repair Pipe

What can you practise if your Flex Pipe on your vehicle is leaking or has broken?

All flexibles on car exhaust will someday fail on you lot, this is non due to poor design or a manufacturing fault. Rather more than so the Job and purpose of the Flexi on an exhaust reaching an end. The Flex Pipe on your exhaust absorbs the movements from the engine, this every bit a results reduces knocking or banging of your exhaust confronting the trunk of the Vehicle. Flexi pipes help with expansions of exhausts, due to loftier levels of heat produced by the gasses exiting your engine. This also helps reduce the chances of your exhaust rubbers and brackets getting damaged due to strain from constant vibration.

These Flexible sections come in many different designs and are referred to in a few unlike terms, generally referred to as a braided flexible, Interlock Flexi (double layered or Triple layered flexi), DPF Flexi (Welded directly on a DPF), Down Piping Flexible or just a Flexi. Exhaust Flexibles are generally positioned close to the engine of vehicle, either immediately after the manifold downpipe, DPF downwards pipe or after a turbo downpipe.

Our Stainless 304 Exhaust Flexi are different to others, only because our flexibles are 100% stainless steel. What you will discover with some suppliers is that the flexi itself is stainless just the ends are mild steel, which as a result with only rust away somewhen.

Nosotros refer to our frazzle flexis every bit ILOK (interlock), these consist of 3 layers, the outside is a woven or braided stainless steel, under this in that location is a ribbed / corrugated flexible and finally on the within the last layer is an interlocked polylock flexible. These combined produce a robust product which will last longer than just the inexpensive double layered flexis.

'Do I need to replace the unabridged section?' The respond is no, then long every bit y'all are able to weld in situa (beingness able to weld or clamp the flexi whilst it's on the vehicle) or are able to remove the factory exhaust section off the vehicle to exist able to acquit the piece of work out on a work bench.

On some vehicles, manufacturers place the flexi department immediately before/afterward a catalytic converter or a DPF. These particular flexibles have to be replaced with a WELD ON flexi every bit there is no pipe to clamp on to. Nonetheless, if your car has a flexible with enough straight pipe on each side, you tin easily cut the old broken flexible and replace it with ane of our CLAMP ON flexi joints.

Our Clamp On flexibles are fabricated to order on a daily footing as we have a strict policy to maintain loftier quality British Fabricated products, we therefore do not import inexpensive versions from abroad. We apply 304 Stainless Steel collars which are modified using specialist tooling to fit the OD of your pipe.

At Exhaust Parts UK we can manufacture exhaust flexibles fabricated to order. Nosotros can supply a full range of 100% stainless steel flexi joints ranging from 1.five" / 38mm to 5" / 127mm diameter. Flexis are measured class the terminate caps on the flexible unit of measurement.

Our Standard Flexi Size Nautical chart

| Weld on | |||||||

| 38mm ten 100mm 1.5″ ten four″ | 45mm x 100mm 1.75″ 10 4″ | 51mm x 100mm 2″ x four″ | 54mm x 100mm two.sixteen″ x 4″ | 57mm x 100mm 2.25″ x 4″ | 63.5mm x 100mm 2.5″ x 4″ | 70mm 10 100mm 2.75″ x 4″ | 76mm x 100mm three″ x 4″ |

| 38mm 10 150mm 1.5″ x 6″ | 45mm ten 150mm 1.75″ x 6″ | 51mm x 150mm ii″ x 6″ | 54mm x 150mm 2.xvi″ x vi″ | 57mm 10 150mm 2.25″ ten 6″ | 63.5mm x 150mm 2.5″ x 6″ | 70mm x 150mm ii.75″ ten 6″ | 76mm x 150mm 3″ x 6″ |

| 38mm x 200mm 1.5″ ten 8″ | 45mm x 200mm i.75″ x viii″ | 51mm 10 200mm 2″ ten viii″ | 54mm 10 200mm 2.16″ ten 8″ | 57mm 10 200mm ii.25″ x eight″ | 63.5mm ten 200mm 2.5″ 10 8″ | 76mm x 200mm 3″ 10 eight″ | |

| 38mm x 250mm one.5″ x 10″ | 45mm x 250mm one.75″ x 10″ | 51mm x 250mm 2″ 10 10″ | 54mm ten 250mm two.16″ x ten″ | 57mm 10 250mm 2.25″ 10 x″ | 63.5mm ten 250mm 2.5″ x 10″ | 76mm x 250mm iii″ x 10″ | |

| Clamp on | |||||||

| 38mm x 200mm 1.5″ x 8″ | 45mm ten 200mm 1.75″ 10 8″ | 51mm x 200mm 2″ x 8″ | 54mm x 200mm ii.16″ x 8″ | 57mm ten 200mm 2.25″ x eight″ | 63.5mm ten 200mm 2.5″ ten 8″ | 70mm x 200mm 2.75″ x 8″ | 76mm 10 200mm three″ x 8″ |

| 38mm 10 250mm i.5″ x 10″ | 45mm 10 250mm ane.75″ x ten″ | 51mm x 250mm 2″ 10 10″ | 54mm x 250mm ii.16″ x ten″ | 57mm x 250mm two.25″ x 10″ | 63.5mm x 250mm ii.5″ ten 10″ | 70mm x 250mm 2.75″ ten ten″ | 76mm 10 250mm iii″ 10 ten″ |

| 38mm 10 300mm ane.five″ x 12″ | 45mm x 300mm 1.75″ x 12″ | 51mm x 300mm 2″ x 12″ | 54mm x 300mm 2.sixteen″ x 12″ | 57mm x 300mm ii.25″ x 12″ | 63.5mm ten 300mm two.v″ x 12″ | 76mm x 300mm 3″ x 12″ | |

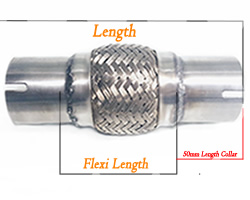

How the flexibles are measured?

Beneath is a table to demonstrate how the flexibles are measured.

Weld on Exhaust Flexis are measured from the finish of the stainless cap on each side.

Clamp On Flexis are measured including the end collars that we have welded on for you. To piece of work out the bodily flexible length subtract 4" / 100mm from the full clench on measurement.

Bespoke Custom Flexi Made to Gild

How To Cut Flexible Repair Pipe,

Source: https://exhaustpartsuk.com/flexi-repair/

Posted by: merrymansublexperve.blogspot.com

0 Response to "How To Cut Flexible Repair Pipe"

Post a Comment